An integrated system enhances accuracy in expense allocation and provides transparency in procurement processes. In the dynamic manufacturing world, tracking sales and revenue involves more than just tallying up transactions. It requires a nuanced approach to account for the intricacies of product costs, varying pricing structures, and the impact of production efficiency on the bottom line. In the intricate world of manufacturing, effective bookkeeping is the silent hero ensuring seamless operations. From financial navigation to compliance, this article unravels its significance and explores unique nuances.

What is different about accounting for manufacturing costs?

- This ensures seamless data movement between the shopfloor, inventory, and the back office, and further simplifies managing your business.

- It includes tax preparation and counseling, as well as tracking spending and earnings.

- Further, investors, customers, and other stakeholders increasingly consider ESG factors when making decisions.

- Strong math and analytical skills are also necessary to interpret complex financial data.

- Further, for smaller manufacturers that aren’t equipped to have full-time accounting staff in-house, partnering with the right accounting service will make a world of difference.

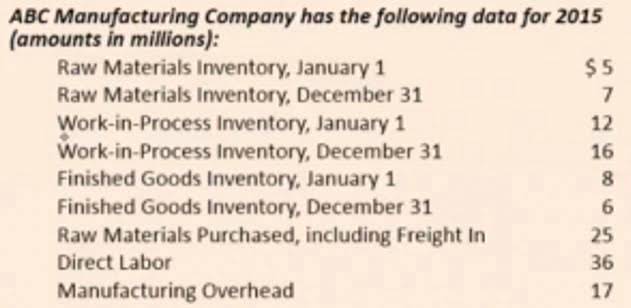

Techniques like First In, First Out (FIFO) or Last In, First Out (LIFO) help adjusting entries assess the value of inventory on hand and the cost of goods sold. An accurate inventory system prevents excess inventory and helps make informed decisions about production needs. Every industry keeps accounting records to manage expenses, income, and tax payments. Key factors include the complexity of financial transactions, the level of scrutiny from tax authorities, and the necessity for precise financial data to inform business strategy and operations. Remote services and shared platforms enable team members to work cohesively from various locations, leading to heightened efficiency and security in financial management. Artificial Intelligence (AI) and machine learning are also becoming increasingly important, transforming the way bookkeepers analyze data and generate insights.

Professional Summary

Include components such as common stock, retained earnings, and additional paid-in capital. Non-current assets encompass long-term investments, property, plant, and equipment. OEE is a comprehensive metric that assesses the efficiency of manufacturing equipment. Tracking OEE provides insights into equipment utilization and identifies opportunities for improvement. However, there are plenty of skilled bookkeepers in the job market, so with a well-crafted job description and competitive compensation package, you should be able to attract qualified candidates.

The Impact of Meru Accounting on the Efficiency and Profitability of a Manufacturing Business.

Outline cash flows related to investments, such as purchases of machinery or equipment. Investments in technology or facilities contribute to the long-term capabilities of the manufacturing business. For manufacturing businesses, this includes revenue from the sale of finished goods. Ensure that revenue recognition aligns with the completion of production and delivery to customers.

See who Robert Half has hired for this role

This entity requires meticulous record-keeping to ensure equity among partners and clarity in financial statements. Yes, we track inventory levels, expiry dates, batch-wise costing, and stock movements. So, for this, we need to ensure that they are not taken into the value of the closing stock. For instance, you can make sure payroll, accounts payable, accounts receivable, and credit cards are all managed appropriately. Accounting for manufacturing companies becomes significantly more efficient and beneficial when these best practices are followed. We at Fincent intend to be a game-changer for the manufacturing industry, by offering a host of benefits that simplify and elevate bookkeeping.

What to look for in manufacturing accounting software

Your accounting system should be adept at capturing these costs accurately for each product, providing a foundation for strategic pricing decisions. Unlike some industries where overhead costs are relatively straightforward, manufacturing businesses contend with the challenge of allocating overhead to the production cost. Bookkeeping in manufacturing must integrate a systematic approach to distribute overhead costs across various products, ensuring accurate cost calculations and pricing strategies. Accounts Receivable and Payable OversightTimely billing and collections are vital for maintaining a steady cash flow. Our bookkeeping services efficiently manage your accounts receivable and negotiate favourable terms with suppliers. This ensures a balance between outgoing and incoming funds to keep your manufacturing operations Bookkeeping for Any Business Industry financially sound.

- This granularity facilitates insights into labor productivity and cost-effectiveness.

- Abnormal costs are often unexpected expenses that occur due to unforeseen events, such as natural disasters, litigation, or restructuring.

- The weighted average cost method calculates the average cost of all units of inventory, considering both old and new inventory.

- I gained a ton of experience and enjoyed the journey, but I knew something was missing.

- This includes recording all transactions, producing financial statements, managing accounts payable and receivable, processing payroll, and preparing tax returns.

- The intent is to consistently assign direct costs based on a logical flow of inventory through the production facility.

Yes, We are presently processing Payroll for Number of clients in US , UK and Australia and take care of complete payroll activities. We prepare a Online Bookkeeping checklist of information required for bookkeeping and send you at timely intervals so as to ensure that we can do bookkeeping faster. Along with that, we also work with many add-ons like Workflow Max, Receipt Bank, Slack, TradeGecko etc., to extend your software’s capacity and improved work experience. Manufacturing organizations need to represent their crude materials and preparation costs.